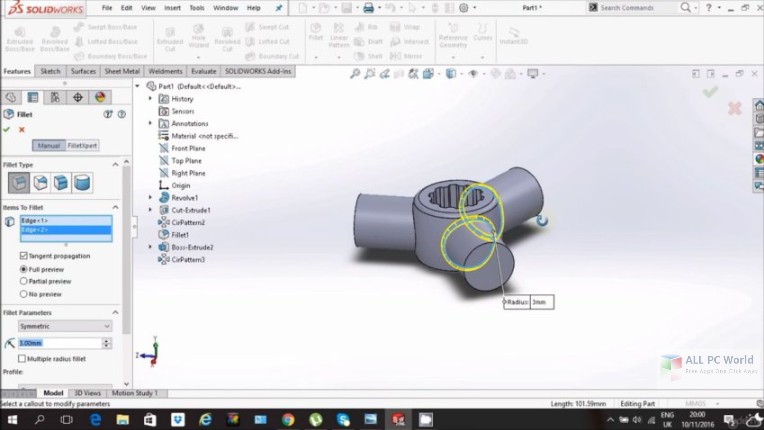

The part can be easily adapted to the needs of processing by, for example, elimination of redundancies from the point of view of processing elements of geometry or by recalculating the executive dimensions of the model into the middle of the tolerance field. When adding any technological data to the SolidWorks model, such as roughness designations, bases, shape tolerances and surface locations, dimensional tolerances, the programmer always has direct access to them, which makes it easy to select the part based on the machine and select ensuring the specified quality of the tool part and cutting conditions. This ensures complete associativity of the model and tool paths, which leads to automatic updating of all tool paths when making changes to the model. The results of the programmer are stored in the same model part or assembly SolidWorks. Processing is carried out directly in the SolidWorks environment and directly on the SolidWorks model. We develop, market, sell, and support over 30 product families in the areas of Customer Experience, Digital Solutions, Secure DevOps, Security & Automation.Overview of CAMWorks for Solidworks Benefits HCLSoftwareis a division of HCL Technologies (HCL) that operates its primary software business.

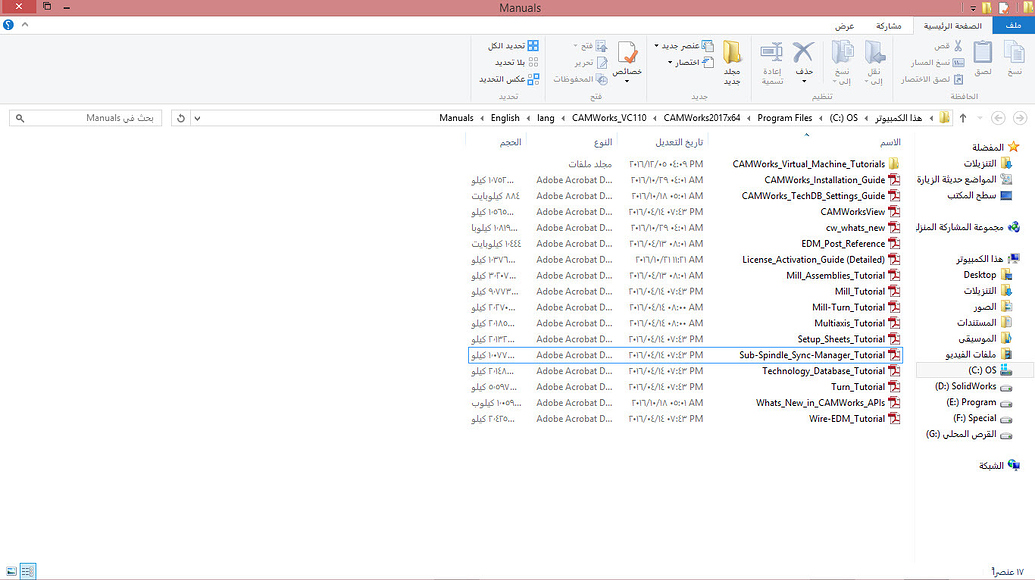

Also, all this functionality can be achieved on a non-workstation computer, requiring very little investment on the hardware side.īetter than Setup Sheets! CAMWorks ShopFloor Machinists will no longer be limited to printed drawings, but rather a single file that contains all information they need. But now CAMWorks provides a more powerful solution with ShopFloor. In the past, Setup Sheets were the best deliverable engineers and programmers could provide to machinists to assist in CNC programming of parts. The software allows simulation of the toolpath, information about fixturing, tooling lists, and more. CAMWorks ShopFloorprovides an interactive environment that machinists can use to fully understand all the machining instructions a part requires.

0 kommentar(er)

0 kommentar(er)